LIQUID’s distribution system consists of a ramp with a system of nozzles with variable flow. This patented solution enables high precision of spreading when the vehicle on which the spreader is mounted moves at high speeds. Two different types of nozzles, one of which is used for spreading immediately after the spreader, and the other for left and right lane spreading, provide the possibility not only of a wide spreading pattern, but also of precise control of spreading asymmetry. Liquid is supplied to the distribution system by a high-flow pump.

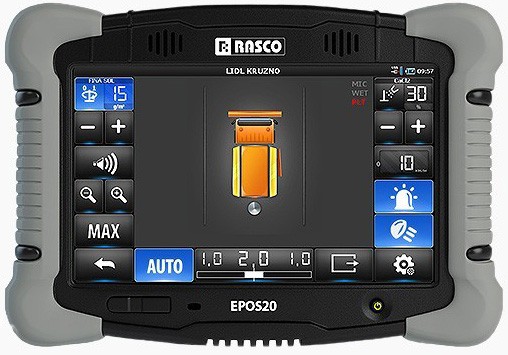

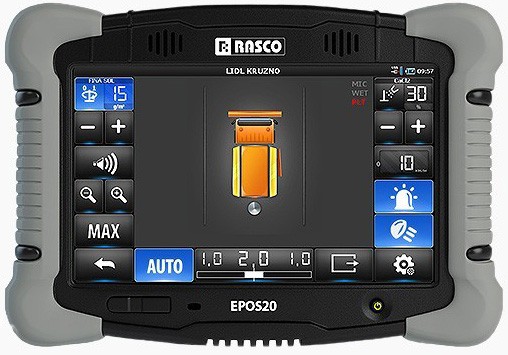

The operation of all RASCO spreaders is controlled by EPOS control units. Their dedicated development by RASCO experts makes them a leading solution for spreading control and monitoring. EPOS control units are used to control all spreader elements. Control of the spreader’s hydraulic actuators with a system of feedback connections ensures highly precise spreading in all work conditions, while the automated calibration system enables fast and simple calibration of spreading precision. Spreading parameters are not lost when the control unit is turned off and can be automatically activated the next time when the spreading process is started.

ARMS is an information and communication system for control, central monitoring, reporting and optimization of activities related to the maintenance of traffic infrastructure. Monitoring of working hours of people and machines as well as of the used resources (such as the used spreading salt, vehicle fuel etc.) in real time creates a unique possibility to quickly decide on potential saving methods. Unchangeable logs protect the user from liability by providing clear information on any taken action, while the reduced consumption of spreading material at the same time protects traffic infrastructure and its surroundings.

It can be carried out through built in vehicle hydraulics, diesel hydraulic power unit mounted on the spreader, or with the fifth wheel.