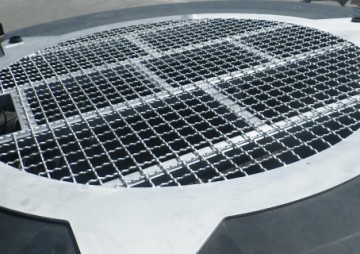

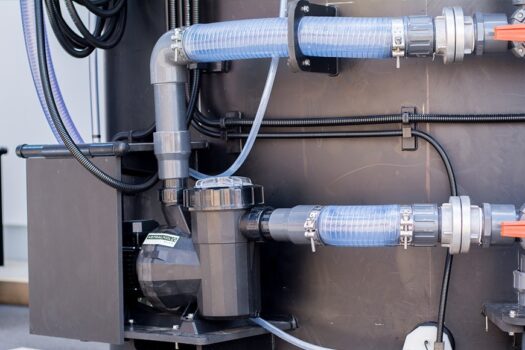

MMS is a device used for preparing solutions (CaCl₂, NaCl, MgCl₂, urea) for pre-wetting or liquid spreading on roads. The mixing of the pre-wetting or liquid spreading is controlled by an electronic automated system for measuring the concentration of the solution.

MMS is made of a special material made of polyethylene that is resistant to ultraviolet radiation, temperature changes and shocks.

The fast preparation of the materila, its ease of use, its rapid filling and emptying and the design that requires minimal maintenance guarantee that MMS is a valuable addition to any snow removal station.